Ross Barrett

Ross Barrett is a project architect with HLM architects working Passivhaus designs for Scotland's Housing Expo. Here he shares an ongoing diary of the construction process.

Cladding...

June 16th, 2010

With the Timber frame essentially complete, the joinery team has begun the task of cladding the buildings. Due to the delay with the windows, we’ve had to carefully look at the sequencing of this as normally the windows would have been installed prior to any cladding works.

Our detail is for a build up of 50x50mm battens and 50x50mm counter battens which support a locally sourced horizontal larch boarding from Russwood in Newtonmore. Due to the open profiled nature of the boards we specified, we also had to wrap the Soft Wood framing in insect mesh to prevent insect ingress. The boards will eventually conceal an external rain water downpipe as well as the extract and intake vents for the MVHR system. We have broken up the horizontal boards into panels which are defined by the vertical larch boards at the jambs of the window and door openings.

Scot Larch Cladding On site

The detailing of the timber cladding took some time to resolve, including numerous discussions with Highland Council to agree on the form of cavity barriers. Building Control unfortunately wouldn’t accept our initial proposals for an intumescent or flexible type barrier, which would have assisted with the drainage, ventilation and drying of the cladding boards, and instead stipulated that all cavity barriers were to be of a solid type.

Dynamight has also been on site to install the first fix of the MVHR ducting layout. We had to coordinate this layout with the structural engineers and timber frame manufacturer to ensure that the holes for the ducting were cored in the correct places within the I-joists and glulam beams. Dynamight has done a neat job and with this in place the first fix electrical and plumbing elements can proceed. The intake and extract vents have also been fitted to the external walls but will require some additional insulation to be replaced around these and fully taped internally to ensure a tight air seal. We also need to fully seal the ducts off prior to the initial air pressure test. When the final test is done however the balanced vent system will be fully operational and connected to the MVHR unit.

First Fix MVHR Ducts In-Situ

All the lead work has been completed on the roof and the bespoke, pressed aluminium gutters are now in place awaiting the fixing of the Marley profiled roof sheeting. Despite wanting to achieve a concealed gutter, we took the decision to keep the gutters and their outlets outwith the airtight envelope – ensuring that if there are any problems in future with leakage/ failure that it will occur outwith the envelope.

Timber Cladding and Lead Work to Gable/ Stepped Gables

Despite some minor problems with the painting of our roof sheets at the Marley Factory, it looks like our roof sheeting is still due to be delivered in the next week. Panic ensued when we realised that the factory was about to shut for a week, but thankfully they did enough to get our sheets through the painting line before the shut down!

We originally wanted to use a recycled aluminium profiled sheet on the roof but struggled with sourcing something of the right appearance and quality. We instead turned to Marley’s profiled fibre cement roof sheeting as we felt it still fitted with the rural aesthetic we were trying to achieve. We have since seen it used on some interesting small scale housing projects in the highlands and islands.

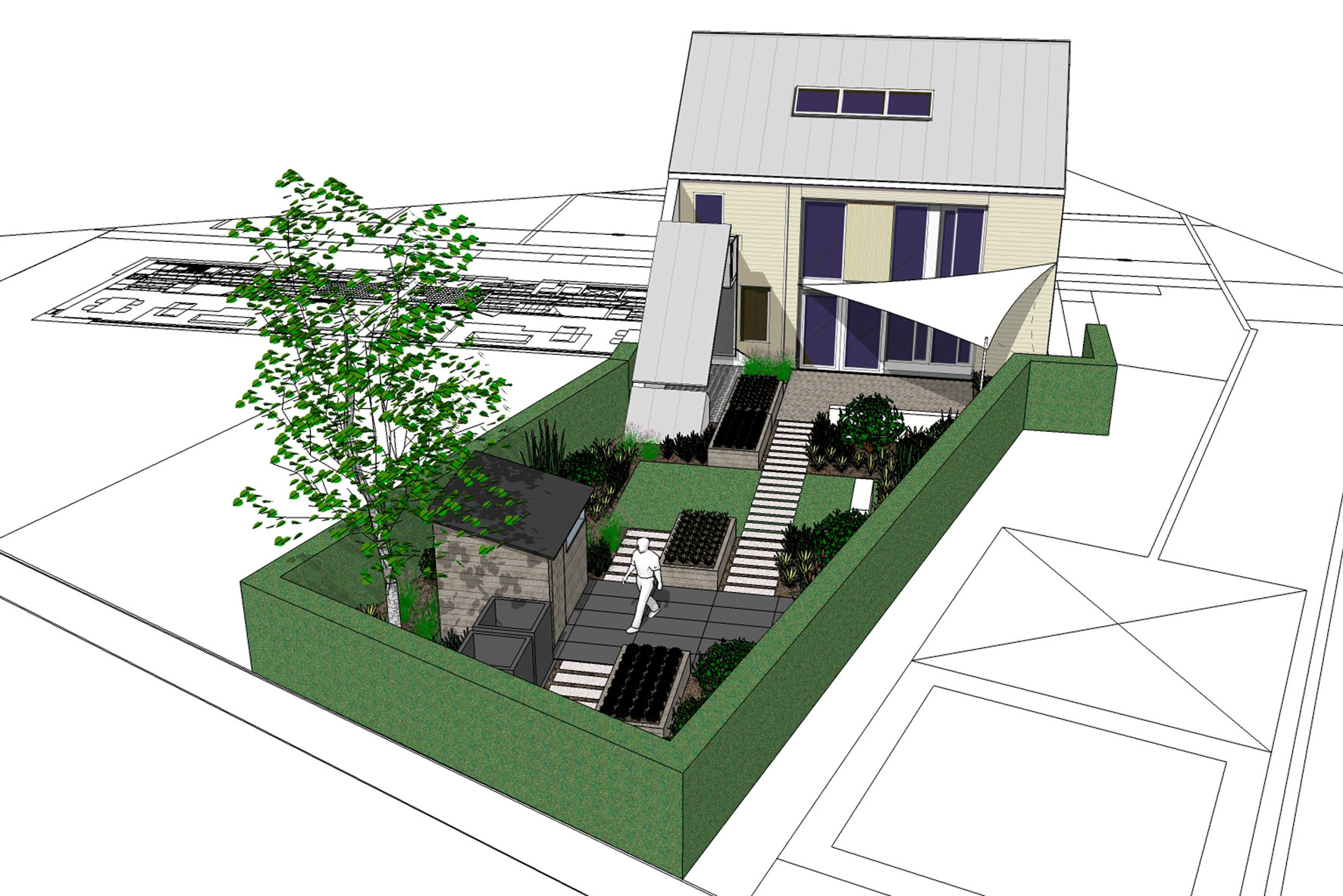

Whilst work progresses on site, we are also continuing to push to find some sponsorship in order to realise one of our gardens which will be planted with local species to enhance wildlife habitats and encourage biodiversity, whilst allotting space for food production and composting. The Highland Housing Alliance has appointed Gerardine and Wayne Hemmingway to design a number of other gardens across the expo scheme, however our ‘sustainable’ garden was part of our competition scheme and with our in-house Landscape Architects, we hope it will become a showcase for sustainable landscape design delivered in conjunction with local suppliers and assistance from the Highland Housing Alliance.

Our Competition Design for the Landscape

We now have a definitive date for delivery of the external windows and doors from Austria and have a team of both local and more experienced German fitters lined up to start fitting as soon as possible.

As soon as the windows and doors are completed (which we think will take about a week), the team will do a final walk around to inspect every window, wall and floor junction to ensure that everything has been sealed as detailed (and maybe even sealed a bit more)! We then expect the first air test to be carried out – so fingers crossed!