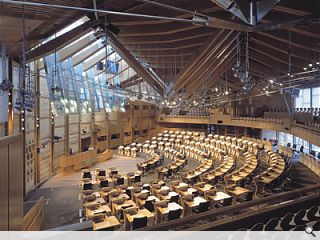

Ben Dawson created the impressive bespoke furniture for the debating chamber and MSPs offices of Scotland\'s new parliament.

17 Jan 2005

by Penny Lewis

Ben Dawson has been making furniture for 21 years. His business has grown from two men in a garage to a highly professional operation with 30 staff, including five trained furniture and industrial designers, located in a roomy factory in Musselburgh.

A number of those thirty employees have spent a good part of the last three years working on the furniture for the new Scottish parliament. They were responsible for the creation of the furniture in the MSPs offices, the debating chamber, the MSPs bar, garden lobby, ministers’s offices and the table in the Donald Dewar library. On the back of Holyrood Dawson has picked up a commission for another prestigious assembly building.

Ben Dawson produced the furniture for the temporary chamber occupied by MSPs until Autumn 2004. However, the Holyrood contracts did not fall in his lap. On the debating chamber bid, Dawson had to undertake a lot of development work at his own risk, each package was run by a different subcontractor and was bid for separately.

A trip around Dawson’s factory provides an insight into the ethos of the business. Demonstrating the process of making a veneer, it is clear that Dawson and staff take pleasure in working with wood. Without getting too romantic there is something distinctly craft-based about the place. Perhaps it’s the bundles of veneer carefully selected from a merchant in Germany, laid out on the floor in piles grouped according to branch and tree.

The business combined Computer Aided Manufacturing with traditional craft skills, it is high technology to manufacture bespoke items. Ironically a growth in technology in the board room has led to increased demand in bespoke furniture in which the technology is integrated.

“It is the software that makes it possible, says Dawson. Dawson’s business moved to computer aided manufacturing when it started work on Holyrood. The factory has five-axis machinery that allows the makers to cut the timber in any plane.

“What is different about us is that we do a lot of design development. We develop the process and the tools to make the product,” says Dawson. Dawson likes to work at certain scales, producing exquisite models that show the entire furniture and scales that illustrate the precise details. On the parliament they worked with models and prototypes, a number of full scale mock-ups can still be spotted around the factory.

“The Holyrood project was challenging, it stretched us, it is exactly what we love to do,” says Dawson. “The unique thing about Holyrood was that the furniture and fittings were designed as part of the architecture, integration was important. It would have been a real shame if, the shell had been designed and the fit out had been standard,” he says.

Dawson didn’t meet Miralles, but worked closely with the EMBT/RMJM team including Joan Callis (EMBT) and John Kingsley (RMJM). “There was a lot of detailed design development involved, we had people working on it full time for up to a year and so many people on the client side were involved in the process of approval,” says Dawson. Most of the designs were drawn by Miralles and developed by EMBT/RMJM. Miralles looked at furniture early in the project and a palette of oak and sycamore was chosen early, but the construction method wasn’t always indicated.

The chamber desks are laminated structures stretched in an Aalto-esque fashion. Dawson’s designers had to deal with the tight curves that were shaped in a variety of different planes and think about how to support the heavy sections. “The architects insisted on ambitious cantilevers, they did not want any secondary structure or support for the desk, the shelf or draw,” says Dawson. The other challenge was incorporating the services with a very simple slim profile. The desks have to carry four systems: power, data, voting mechanisms and voice. Services were housed in a 30mm slot cut into the panels.The laminate is made up of layers of European oak and sycamore, the sycamore is laid in two directions, known as a constructional veneer. There are eighteen laminations in a panel with two layers of the dark laminate together.

The design is rigorous, the wooden catch used to support the desktop of the structure is carefully considered and the hinge attached to the desktop is craftily concealed. “Nothing is standard, where you have a standard microphone you have to produce a custom made mount,” says Dawson. “The MSPs desks are like a piece of architecture. They have a continuously varying splayed edge, so all of the machine work had to be spot on. The forms are free flowing, but they are very precise,” he adds.

Photography by Keith Hunter

Back to January 2005

Browse Features Archive

Search

News

For more news from the industry visit our News section.

Features & Reports

For more information from the industry visit our Features & Reports section.