Gallery: "specification"

The process of re-badging and re-launching goes on, relentlessly. A few years ago while I was working on buildings for mental healthcare, I studied the evolution of asylums for the insane. It’s a specialist field, with lots of expert knowledge which I barely touched on, but it has produced a fair number of under-appreciated buildings including MacMon’s beautifully-designed facility at Murray Royal in Perth, which was completed a few years ago.

One of the most striking things I discovered was the continual renaming of places for people who have psychiatric issues. Insanity became mental illness, asylums became hospitals. The names changed many times, from madhouses to lunatic asylums and idiot colonies, then institutions for mental defectives, hospitals for the mentally handicapped, then psychiatric units and now mental health facilities. Changing the names made little difference to patients – it was a matter of semantics for politicians and administrators – but improving the buildings in which they’re cared for did. I can see a parallel in today’s sustainability movement.

As Michael Pawlyn wrote in the RIBA Journal in 2019, signing up to Architects Declare signed you up to “Regenerative Architecture” – but what is it and how do you achieve it? He quickly admitted that, “For those of us who have been involved in sustainable design for 30 years or more, it is painful to accept how badly sustainability has failed to prevent the multiple environmental crises from worsening.” That gets close to the truth of why Sustainability (which used to be known as Eco-friendly Design, and before that as Green Architecture) has been re-badged as Regenerative Architecture.

Architects Declare and their allies believe Sustainability has failed – so they’ve decided to rebadge it. But that’s a misconception. Sustainability hasn’t failed; it’s a multi-decade project and still a work in progress. Buildings today are far more sustainable than they were thirty years ago. Sustainability has achieved a great deal – albeit not the total overthrow of capitalism, which Extinction Rebellion and their fellow travellers would like to see.

Meantime, “Regenerative” in this context reveals breathtaking arrogance and ignorance within our profession about what regeneration means. For example, one of the few specifics Michael Pawlyn provides is to suggest building with materials made from atmospheric carbon: he cites wood as an example. But chopping down trees is De-Generative, because it reduces the natural world’s ability to absorb stormwater and CO2. Only by planting more new trees than you fell can you regenerate the ecosystem’s ability to absorb. That's a crucial caveat.

Then you have solar panels, which are a red herring when it comes to Regenerative Architecture. They’re certainly helpful to generate some electrical power for buildings, which may mean using less coal- and gas-powered generation; but that’s a non-issue in Scotland where almost all our electricity is generated by hydro stations and wind turbines, and nuclear power. Regardless, solar panels can’t regenerate the natural ecosystem in the way that planting shrubs and herbs creates a habitat for insects and helps to absorb water and CO2.

Biophilia and biomimicry have also been offered up as examples of Regenerative Architecture. In the early 2020’s, they became fashionable among the mega-consultancies which offer workplace design to the multi-national corporations which fill up Grade A space in our big cities. For them, supposedly regenerative design followed a formula of including some raw timber, rather than painted finishes. Living walls, often using reindeer moss or something similar, or fake green walls which approximate a living wall. A view to the outside, if you’re lucky enough to have one from your deep plan floorplate; or artificial lighting which follows circadian rhythms, if you’re not that lucky. Plus a few pot plants.

But no-one from Architects Declare has explained how a newbuild central London office tower can help to regenerate the natural ecosystem, so Regenerative Architecture joins a series of straw men and pails of greenwash which practices parade on their websites. The RIBA 2030 Climate Challenge, B-Corp, Article 25 and so forth. The whole scene is rather like a ceremony in the Wacky Races cartoons: each time Dick Dastardly needs to motivate Muttley, he gives him a medal which is proudly displayed on the dog’s puffed-up chest. Re-badging is a distraction which misses the point of what the term Regenerative actually means.

For once, I can speak from direct experience. All the generations that preceded me worked the land, but while some were farmers, my direct ancestors on Dad’s side were mostly market gardeners. During the 18th and 19th centuries they relied on horsepower for ploughing, crop rotation to keep down diseases, and animal manure for fertiliser. My grandfather was the first to buy mechanical tractors, motor lorries and use chemical fertiliser.

Market gardening isn’t like farming. The latter is extensive agriculture, whereas market gardening is intensive horticulture – in other words, using a few hectares to grow higher yield crops like fruit and vegetables, rather than a few hundred hectares to grow cereals, or grass to support grazing sheep and cattle. My family grew vegetables like carrots, turnips, tomatoes and salads; fruit like strawberries and apples; and flowers like chrysanthemums and helichrysums.

My Grandad, and my Dad after him, saw the introduction of NPK fertilisers (nitrogen, phosphorus, and potassium) and chemical insecticides like DDT and 2,4D, along with pre-emergence weedkillers make a big difference to crop yields. DDT was introduced when Dad was a teenager, and it was a tremendously effective insecticide. By the time he was in his 30’s, DDT had been banned, along with many others like Aldrin and Deldrin. We now understand that these toxic chemicals are biocides: they don’t just harm the species we’ve decided are “pests”, they also also kill helpful pollinators and destroy friendly bacteria in the soil.

These chemicals, which made post-War horticulture less back-breaking and more profitable, were counter-productive. The latest agri-chemicals to be banned (just the other week) are neo-nicotinoid pesticides, but none of this is news. For example, Strawberry Cultivation, written by Edward Hyams in the early 1950’s, was one of my Dad’s favourite books. Its opening lines read, “If man ever has to give an account of himself as chief tenant of the planet, he will be hard put to it not to show himself deserving of severe censure. He has destroyed forests, befouled rivers and seas, created deserts, hunted, tortured and even exterminated many of his fellow species, all with complacent self-satisfaction.”

My Dad and Grandad observed a cycle where most of the wonder chemicals introduced during the 1940’s and 50’s were banned during the 1960’s and 70’s: but meantime an alternative had opened up in the US. A movement called Conservation Farming emerged, which was a form of permaculture later called Regenerative Agriculture. By coincidence, one of the companies which contributed to it was Allis-Chalmers, an engineering firm in Milwaukee which was founded by a distant relative. He escaped from a life of tenant farming in Angus by emigrating to Chicago in 1841, and decades later his company had grown into one of the biggest of its kind in the world. I mentioned one of their earthmovers here.

A-C is credited with designing, manufacturing and selling the first commercially successful no-tillage planters, in 1966. The principle is really simple. Rather than driving a tractor through the field four times – once with ploughs, then with harrows, then with fertiliser, then a final time with seeders – No-Til barely disturbed the soil, and did everything in one pass. That saved time, money and fuel and most importantly it didn’t open up the soil which would have allowed nutrients to leach away. Thanks to No-Til, natural nutrients and moisture were retained and the topsoil was able to regenerate itself, naturally. By contrast, conventional ploughing degraded the soil, which meant more artificial fertilisers and chemicals were needed.

Trademarked as the Allis-Chalmers No-Til system, three toolbars were carried behind the tractor. The first had a series of coulters developed by A-C engineer Maynard Walberg, which sliced through crop residue or sod to prepare a narrow strip of soil, rather than churning up the whole field. The second toolbar carried fertiliser boxes which sprinkled a small amount of fertiliser only where it was needed, in the seedbed. Planter units were attached to the third toolbar. As an aside, the story of how Allis-Chalmers developed the No-Til planter and pioneered regenerative farming is a powerful argument for the good that enlightened capitalism can do, too.

Leaving the soil as undisturbed as possible is truly regenerative: and perhaps only foresters, ecologists, farmers and market gardeners, and conservationists can help to regenerate the natural environment in a true sense. By comparison, architects are kidding themselves: the glass and stone and steel and dead timber which we make buildings from can’t regenerate communities of plants, animals, birds and fungi. Misunderstanding what Regenerative means isn’t just semantics – it’s crucial to understanding the issue, in exactly the same way that the so-called “fireproof” insulations used at Grenfell Tower weren’t Class A1 rated, so people died. “Car-free” developments aren’t really car-free, if residents just park their cars on adjacent streets.

I hate to make predictions this early in the New Year, but I can see the current generation of dogma-driven architects repeating the mistakes of their predecessors, just in a different way. What was labelled as the worst of 1960’s architecture – such as Sam Bunton’s Red Road flats and Basil Spence’s Hutchie C tower blocks in Glasgow, T. Dan Smith’s masterplan for Newcastle, the Hulme Crescents in Manchester, and Ronan Point in London – was blamed for destroying inner city working class communities and creating brand new slums. Likewise, claiming that we can regenerate the earth by building on it is intellectually dishonest and plain wrong.

In the 1960’s, Modernism promised to remake the world, by adopting a new paradigm. We replanned cities to eliminate slums, then housed people at high density in tower blocks and deck-access slabs, prefabricated these buildings in precast concrete factories, and made it easier for cars to get around. But the streets in the sky turned into wind-blasted nowheres, precast large panel systems turned out to be difficult to assemble accurately on site, and electric underfloor heating turned out to be too expensive to use. Some buildings leaked, others were poorly insulated, some were structurally unsafe.

In the 21st century, Sustainable architecture promised to remake the world, by adopting a new paradigm. We replanned cities to eliminate private cars, then tried to raise inner city densities by prefabricating medium rise buildings in SIP factories. However, the combinations of membrane which make them airtight but vapour permeable rely on faultless workmanship on site. When mechanical ventilation with heat recovery (MVHR) systems fail due to poor maintenance, when external wall insulation (EWI) systems fail due to being poorly applied, and when heat pumps are incorrectly installed in poorly-insulated, leaky old buildings – they don’t work.

I’ve got personal experience of MVHR problems and modern EWI systems which failed in the most dramatic way – I was a small part of a team brought in to rectify the problems. That underlined to me that Sustainability is a work in progress, rather than something to discard. If we don’t recognise the limits of our competence and show some humility by doing simpler things more effectively, the results will be just the same as during the 1960’s: cold houses where old people live miserably through winter, and damp houses where children develop breathing disorders.

Before we ditch sustainability in favour of a new badge, we need to get the fundamentals right. Aim for Fabric First, rather than bolting on complex heat recovery systems in order to scrape through the SBEM calculations. Demolish as little as possible, instead upgrade everything we can – and push Westminster to abolish VAT on refurbs in order to encourage that. Finally, specify Scottish products and materials every time – not imports from China for “value engineering”.

The concepts behind sustainability are often misunderstood – sometimes wildly so. It’s been tough enough to master sustainable materials while we improve U-values and airtightness, without starting again from scratch with Regenerative Architecture: a mixture of misconceptions, extravagant promises to save the world, and greenwash.

That notwithstanding, Happy New Year. :-)

Compared to its dysfunctional cousin south of the Border, the Building Control system in Scotland is more stringent. You’ve never been able to build high rise blocks with only one means of escape in Scotland, and our Building Warrant process wasn’t hived off to the private sector by Thatcher.

In my experience, Building Standards departments communicate well with architects: those I’ve dealt with recently in Aberdeenshire, the City of Aberdeen and City of Dundee organise updates and seminars for architects, explaining changes to the regulations and asking for our feedback. We attended an update session a few weeks ago, when the Team Leader at Building Standards ran through upcoming revisions to the Technical Standards.

Three things stuck out: the reversal of the wood-fired stoves fiasco, the long-term implications of the Grenfell Tower fire, and the need to remove politicians from the room when procurement and construction are discussed.

Firstly, fitting wood-fired stoves in new builds is no longer banned. I could go into a political rant (at the risk of death by boredom) about the misguided impulse behind the proposed ban, but just like scrapping the target to reduce greenhouse gas emissions by 75% by 2030, it demonstrates that the folk who come up with these policies aren’t talking to those who have to implement them. Between them lies a yawning gap between declarative statements and practical action – a gap traditionally occupied by politicians.

In this case, while policy-makers thought they’d found a clever way to penalise rich folk who build fancy houses, most of us saw the ban as a first step towards the eventual banning of solid fuel stoves, back boilers, and open fires. The reality is that solid-fuel stoves and open fires are used by many people in the overlooked 95% of Scotland’s landmass – the part beyond the big cities which is called the countryside. People there have to be pragmatic about how they heat their houses, because you still get deep snow up the glens and in the Highlands: sometimes the LPG tanker, or coal lorry, or oil tanker, or even the heat pump repair man, can’t get through. So you need to have a back-up, such as solar panels, or open fires, or a solid fuel stove.

The only experience I have of solid fuel was at my grandparents' house in an Aberdeenshire village. There were fireplaces in several rooms, but I only remember a couple downstairs being lit in winter – you can imagine that the house was a bit chilly, but my grandparents were hardy and didn't seem to notice. They had a shed for coal, and another shed for logs, but no central heating – the village had no mains gas. They heated their house the way several generations of Essons had done before them.

Secondly, Building Standards introduced us to a new role, the CPM or Compliance Plan Manager – a new acronym, confusingly similar to but distinct from CDM or CPD. Unlike the earlier Planning Supervisor, CDM Coordinator and Principal Designer roles, this one carries heavy consequences for getting it wrong: likely up to a £50,000 fine and two years imprisonment. After the presentation, I asked the Team Leader whether the Scottish Government foresaw that architects could fulfil the CPM role. He believed yes we could, but we both agreed that the liabilities and hence the professional indemnity insurance premiums could be off-putting.

Is the CPM another opportunity for architects to retain part of their traditional role, which has gradually been chipped away by project managers, Planning Supervisors and CDM Coordinators? Or is it a poisoned chalice, which will see CPM’s in the dock when something tragic happens on site or years later when the building is in use? Time will tell.

Finally, the repercussions of the Grenfell Tower Report were discussed at length. While the report heaps criticism on the architect, Building Control, K&C Council, the contractors and suppliers such as Kingspan, Arconic and Celotex – it’s also notable for not tackling the political and legislative failures which resulted in Grenfell Tower being designed and built the way it was.

For example, who allowed English tower blocks to be built with a single means of escape? In Scotland, all tower blocks have two separate means of escape. Architects and contractors can only follow the rulebook they’ve been given. Who allowed plastic foam insulation to be used in over-cladding tower blocks? Surely any insulation used in construction, especially on mid-rise and high-rise buildings, should be Class A1, in other words completely non-flammable? Shouldn’t plastic foam insulation be blacklisted, like RAAC and the structural use of woodwool slabs were?

Most of all, who allowed the public sector to procure construction work using Design & Build contracts? Most people I’ve spoken to feel that’s a fundamental problem, the root cause of dangerous buildings. The client asks for a safe building, the architect designs a safe building, but once he or she is novated to the contractor, cost rather than quality and safety becomes the driver. Whether or not an architect is “reasonably competent” or “suitably experienced” or whichever description the construction lawyers select – once they’re working for the contractor, architects can only argue so many times about quality and specification before they’re slapped down.

To make matters worse, in many cases the D&B contractor’s cost savings don’t benefit the client – due the way that the contracts work, unless there’s an explicit clawback mechanism which shares the value engineering savings between client and contractor, they go straight onto the contractor’s margin.

Government is in charge of legislating on Building Standards – so perhaps they should shoulder some blame for allowing English tower blocks to be built with a single means of escape. Government is in charge of legislating on building materials testing and classification across the UK – so they should shoulder some blame for plastic foam insulation being used. And most of all, government is in charge of public sector procurement – surely they must shoulder blame for allowing Design & Build contracts to be used on tower block refurbishments?

We may not work south of the border, and we might not be working on tower blocks (although I’ve done both at different stages of my career) but the shockwaves of Grenfell Tower are being felt across Scotland’s Building Standards system, too. For what it’s worth, I think we should be listening to the advocates of Fabric First, and rapidly upgrading as much of the existing building stock as we can, using much non-flammable insulation and improved airtightness. That way, the heating loads of buildings will shrink to the point where their CO2 emissions are less of an issue than they are now, and people’s energy bills will shrink, too.

As to fixing political meddling in the construction industry – good luck with that.

A few months ago, I spotted the earthly remains of an Artemide uplighter listed for sale on an online auction site. I enjoy tinkering and assembling things from bits – on a smaller scale but in the same way that folk with acres of land buy old bulldozers, saving them from the scrapheap and then restoring them to running order.

I already had the components of roughly one-and-a-half uplighters, including three glass shades which were different colours. In theory, this was an opportunity to put together two complete lamps, because the listing noted that the vendor had bought a new glass shade from Artemide but never got around to fitting it to the lamp. The new one matched one of the three I already owned, and parts of another uplighter were chucked in for good measure.

Ebay and other online auction sites such as Vinterior and Etsy are a good source of second-hand furniture and fittings – but the latter two are awash with dealers, plus amateurs with greedily optimistic expectations of what things are worth. Ebay has some of those, too, but there are also lots of folk simply trying to clear out their loft or garage. Their prices are much more realistic, but Caveat Emptor still applies.

After some haggling, I bought the lamps and arranged to collect them a few days later. The address was a large house in the leafy western suburbs of Edinburgh, and a cheerful chap in jumbo cords and cardigan met me at the door with a box of lamp components. He apologised that some were a wee bit rusty, after having lain abandoned in the garage for a few years.

It wasn’t difficult to read between the lines. The glass shade had broken and he’d decided to buy a replacement, without checking first how to fit it. Perhaps it came with instructions, but those had been lost along the way. Perhaps husband or wife were practical folk who are good with their hands – but on the evidence I saw, that seems unlikely.

Maybe they’re just clumsy, a throwback to our pre-historic Neanderthal ancestors who lacked the ability to use tools. We all know folk who trip over their feet and slice their fingertips while chopping onions. An alternative is that they’re giant-brained people who have evolved beyond Homo Faber, and have since lost the ability to use tools. Perhaps you can blame genes, upbringing, or the class system for the fact that some professional people don’t value practical skills, and worse still, they transmit this disinterest to their children.

So the folks in Cramond may have evolved to become more interested in reading highbrow novels about a shape-shifting petty criminal in Georgian London, or attending chamber music recitals in the Queens Hall, or become pre-occupied with the configurator on Range Rover’s website, trying to decide which combination of colour, trim and accessories they’d prefer when the time comes to replace their spaniel-scented Volvo estate. Regardless, it seems they have no manual dexterity when it comes to domestic repairs.

Once I got home, I unpacked the lamps from the box and disgorged a Sainsburys-bag-for-life, which was full of seemingly random grub screws, washers and nuts. I scrutinised the partly-dismantled uplighter body to see what needed fixing. Someone had already loosened the nuts which located the terminals for the linear halogen lamp, and in order to free the little casting the terminals were mounted on, they’d also loosened the large nut which holds the shade by clamping together a sandwich of glass, silicon gaskets and aluminium.

But then they’d evidently got stuck. The wires which feed the terminals have crimped connectors on the end which didn’t quite fit through the central hole. So they’d just chopped the connectors off! Fortunately, I already had a complete shade: using a pair of Lindström needle-nosed pliers, I gently compressed the metal tangs which held the crimps within the connector, then released the wires and guided them through the hole. I was able to swap the wiring and connectors between the uplighter bodies. Using the right tool, the job took five minutes.

Fixing the uplighter gave me a moment of intense satisfaction, as I’d probably saved it from the skip.

A few weeks later, a spring on the loft ladder gave up with a loud bang. I’d been running up and downstairs with rolls of Knauf Loft Roll 44, as I try to bring the house up to current day insulation standards. So far, I’ve laid 350mm of glasswool quilt behind the uprights of the roof structure where it tapers out to the eaves, and 150mm in the depth of the first floor joists along the centre. I had to lift about 60 square metres of chipboard deck before I could insulate that central part of the floor, though.

The loft ladder was made about 50 years ago by Ramsay Ladders in Forfar. In Scotland, the Ramsay Ladder has become synonymous with loft ladder: it’s a metonym, in the same way that “Hoover” and “vacuum cleaner” were once interchangeable. I drove up to Forfar and bought a pair of new springs, and the helpful maintenance chap at Ramsay Ladders explained how to fit them: I needed to loosen some fixings whilst keeping my knee on the end of the radius arm, otherwise the one with the good spring would rebound and break my wrist.

He asked if I’d replaced springs on a ladder before, then narrowed his eyes when I explained that I was an architect. I thought I’d reassured him that I knew how things went together; but his experience was that architects know more in theory than they do in practice. He shared his thesis that architects should spend a few months working on site during their training. They should spend time working with an electrician, then a joiner, then a bricklayer, and so on.

It’s a fair point. If you know how a building fits together in practice, it’s bound to improve how you design and detail. But that’s partly why the Year Out exists, so that students get some practical experience and also a feel for what the reality of building things is like. The flip side of that is that the Year Out can ruthlessly expose student architects who have no practical aptitude, and little interest in actually building things. At this point, they may realise that an academic career might be more suitable – and there’s no shame in that.

Thankfully, just like the little needle-nosed pliers in my tool box, I also have a set of Whitworth combination spanners, so replacing the Ramsay Ladder springs was straightforward. For a second time, I was pleased with myself – until I dropped the big plastic drawer which holds frozen loaves in the bottom of the freezer. The polycarbonate panel smashed, so I ended up having to buy a new one. That’ll teach me to be judgmental about other folks’ lack of dexterity, because it proves that I’m a ham-fisted blockhead, too.

Neither does it bode well for my next task, which is to insulate the solum. But since the house was constructed with a gas-fired warm air heating system and underfloor ducts, I’ve got some hard labour ahead, because I've discovered that the ductwork is still in place in the solum crawlspace. You can imagine how much fun it will be to cut up the ductwork using a hacksaw, while lying on your side on a bed of bitumen and furnace ashes…

While legislators down south wrestle with how to implement Judith Hackitt’s Golden Thread, the aftermath of the Grenfell Tower fire is being felt in Scotland, too.

In her Building a Safer Future report, which was published in the wake of the fire at Grenfell Tower in London, Hackitt recommended the introduction of a “golden thread” to ensure that building safety is taken into account at every stage in a building’s lifecycle. At first, it wasn’t clear how that would work in practice, but it turns out that the impact is far reaching. Even though the requirements of the Scottish Technical Standards are seen as being slightly tougher than those down south, and the Building Control system here is more strictly applied than the third party verifier model used to date in England, they have lots of things in common.

Fundamentally, we buy the same materials and products manufactured by the same corporations and sold by the same merchants. Despite the fact we practice in Scotland and are not directly affected by Hackitt’s report, we’ve discovered that it's no longer enough to state that a material complies with the relevant standard. Now we also need to produce fire test certificates for everything we specify:

• Intumescent paint

• Fire-rated windows

• Fire doors, of course

• Sandwich cladding panels

• MF partitioning systems

I’ve always tried to avoid sandwich panels, due to their lack of fire resistance, the plastic foam insulation inside each one which is environmentally nasty thanks to the blowing agents used in its manufacture, and the near impossibility of recycling panels at the end of their life – but we’re sometimes forced to use them, to meet a client’s branding requirements. American motor manufacturing corporations even have a habit of specifying US cladding products which simply aren’t available here – and even if they were, they wouldn’t meet our standards because they haven’t been fire tested in the UK.

However the last category, MF partitioning, has proven to be the trickiest. Over the past two or three years, manufacturers have quietly re-tested and re-badged all of the walltypes in their White Book, Green Book or Pink Book. Suddenly, internal wall constructions which we’ve used for years to achieve 60 minutes at 6 or 7 metres high, no longer comply. As a result, all the internal wall constructions which we specified during the Covid era, marked up on the walltypes drawing, then detailed, have had to be revised.

Where we can’t get Warrington fire test certificates for particular build-ups, such as the fire-resistant “umbrella” where a compartment wall head hits an existing sandwich panel roof, we needed to get fire engineering assessments which took much longer than we expected. Then we discovered that one of the major plasterboard firms no longer markets horizontal Shaftwall, which is proved to be an acute hassle since it’s essential to form the fireproof lid over the fire escape stair enclosures, if you’re to avoid using wet trades and heavyside materials. So now we have a mix-and-match building, using systems from rival manufacturers, which won’t greatly please the contractor’s buyer.

I guess that’s one difficulty of working on refurbishments of modern commercial sheds, which I’ve had to do once or twice recently – rather than taking either an older industrial building with a concrete frame and brick walls, or designing a newbuild on a clean sheet of paper. The older industrial is bombproof: the frame and walls are inherently fire resistant and will achieve 4 or more hours of fire resistance, effortlessly. The newbuild can be engineered to do whatever’s required from the outset.

Unravelling the Golden Thread means that more product information is needed at an earlier stage of the scheme, and each Building Warrant application becomes a larger package which takes longer for the BCO to assess – and at the very end of the project, O&M manuals will grow to be two or three times their current size. Architects, structural and fire engineers have to put together a narrative, telling the story of how they struggled to make relatively modern retail sheds and warehouses comply, and documenting the increasingly complex systems they needed to do it. However, if that saves even one life, it's a price worth paying.

We're about to start investigating a high profile building with a failing roof, which I daren't name, even for the best of reasons. It's a piece of "iconic" architecture by a Big Name, and already I notice a touch of schadenfreude from people who always suspected that the Big Name didn't have the architectural firepower to detail junctions and penetrations or the nous to handle the weathering of complex surfaces.

So it proved, and a few years after completion the envelope appears to be staining badly, and leaking through rooflights and perhaps other joints and vertices too. It has an unusual form, but pure “form-making” is the preserve of second year students and paper architects; fabric design takes longer to understand and the further into practice I go, the more I realise I’ve still got to learn.

Part of the issue is that the building with the failing roof is a one-off in every sense. It’s an experimental prototype, probably the only building of that ilk the practice has designed, using systems and techniques they won't use again. It’s a Mark 1 building, when the client really needed a Mark 10 version with the detailing refined and all the problems ironed out.

So I come back to something I've written about here before, perhaps to the point of repeating myself. An architect who doesn't master materials and detailing can never really be a fully-formed architect. If you don't know which material or system is appropriate for the form you’re drawing, all is lost. You’re just like a would-be musician who hasn't progressed to read music, so plays everything by ear.

Until he reached his late 30's, my father was a commercial grower: firstly in a market garden producing flowers, fruit and vegetables for the wholesale market, then later in commercial landscaping where he was involved with nursery work and planting schemes. As an aside, Dad’s career evolution showed me there’s hope for late developers: another example was Howlin Wolf, who was 42 years old when he signed to Chess Records.

The final project my father worked on before he shifted industries was the landscaping of the Scottish Amicable site at Craigforth on the edge of Stirling. Craigforth is about to be razed for redevelopment and I have conflicted feelings every time I drive down the A9: the trees and shrubs around the buildings are some of the last living links with my Dad, and that's particularly poignant at this time of year.

Hard landscaping was important at Craigforth and other projects he worked on in Dundee and Glenisla, but my father’s main raw materials were plants. Three years ago when I sorted through things after he died, I found some old seed packets which he had set aside. Not the A6-sized consumer packets with luridly colourful photos which contain around 20 seeds, but miniature brown paper envelopes, each little bigger than an old-fashioned railway ticket, but with four or five gross of seeds in each.

One packet was marked “Arkwright Ruby”. I had to look that up, and discovered it was an F1 hybrid Viola. An old-fashioned cousin of the pansy and the violet plant, it flowered for six months at a time, producing profuse, coppery-maroon petals. Dad had a connection to Carter’s Seeds of Raynes Park in London, but this particular packet came from Thomson & Morgan of Ipswich.

My father also had dozens of monographs dedicated to plants and plant families, and he kept a note of varieties, yields, successes and failures. Seed packets along with diaries, leaflets, flyers and bulletins from the Ministry. By recording how well every crop did each year, he built up a record which became more detailed as the years passed. Each market garden, croft and farm has its own unique microclimate and soil, slightly different to those around it. For that reason, textbooks can only be so helpful and beyond that point, empirical information is vital.

I don't think it's too stupid to suggest that architects should be this close to their raw materials, too.

How many architects can say they walked the context before designing a building, observing how well similar materials used on similar aspects have lasted? Paddy Hislop at TRADA is a really helpful source of advice on timber cladding; for other materials you have to develop relationships with experienced suppliers. That's how I learned about plywood, from one of the original directors of Rembrand Timber, who entered the industry just after the war when factories which made de Havilland’s timber aircraft were re-tooled for furniture and construction.

So before I even considered a form-making exercise, I’d make sure I really understood which systems were appropriate to achieve it – and after I’d built one, I’d monitor it in order to learn how to improve it the next time around.

Sometimes it feels like trying to resolve competing demands, like thermal performance against the limited depth available in a wall or deck build-up, is like trying to post an octopus through a Venetian blind.

The push to improve U-values has run all through my career. We scoffed at the buff-covered copies of the Building Regs which the greybeards had, prescribing walls which didn’t even achieve 0.45 W/m2K. The old-timers each had their own dog-eared copy, but when the new Technical Standards came in later in the 1990’s, the office only bought one copy and it came in a ring binder: all the better to swap pages out each time the thermal performance of walls and roofs became more stringent.

As values rose from 0.45 to 0.3 then 0.2 W/m2K, how best to achieve them became a concern, because material performance didn’t improve so insulation thicknesses just kept increasing. I vaguely remember 100mm kit walls, which soon became 140mm studwork, then 200 or 250mm JJI joists were used as studs to accommodate increasing depths of glasswool, cellulose or rock fibre.

As a result, we've always been up against it with wall linings and timber kit build-ups and rather like computers during the 1990's, as soon as processor speed and RAM increased according to the so-called Moore’s Law, the gain was more than absorbed by a more sophisticated programme carrying out ever more intensive tasks.

Similarly, despite pressure to move from glasswool and stonewool to polystyrene (EPS or XPS) polyurethane (PUR), then poly-isocyanurate (PIR) foams, which offer progressively better R-values: as soon as thinner insulation was developed, the minimum U-value improved too, so you needed more of it. The net gain in footprint won back was nil, because materials technology and the Technical Standards had fought themselves to a standstill.

However, what feels like one of the few genuine pieces of materials tech progress in recent decades has become a commercial proposition: Vacuum insulation, or more accurately evacuated insulation. As you may remember from the teacher’s explanation of the Dewar Flask in Higher Physics, a vacuum, or the absence of air, has no thermal conductivity and that makes it the perfect insulant. Nothing can pass through a vacuum apart from radiation, so no heat is lost to either conduction or convection.

Vacuum insulated panels (VIP’s) have been in use for a few decades in refrigeration plants, cold stores, cryogenic freezers and the like, manufactured by companies like Morgan Advanced Materials (the UK company which was previously known as Morgan Crucible). They’ve only made their way into the building industry in the past decade or so as firms like Kingspan and the German firm Va-Q-tec began production. Around 2005, VIP’s were introduced into the construction industry in Germany, Switzerland and Scandinavia, to begin with as deck insulation on balconies and other locations where deep build-ups cause detailing headaches.

VIP’s are made from fumed silica sand, which forms a porous matrix from which more than 99.999% of the air is evacuated. The silica is encapsulated in a vacuum-tight envelope made from aluminium foil, and the key thing is to make sure that isn’t penetrated by a nail or screw. In 2022 terms, silica is inert so it won’t harm the environment, and it’s not flammable so it won’t go up in flames, like foam insulation frequently seems to do.

In thermal performance terms, vacuum panels have a lambda value four or five times better than the best foam insulations, and one analysis demonstrated that a VIP board 20mm thick achieves the same thermal performance as mineral wool or PUR insulation board with a thickness of 185mm.

At the same time as VIP boards emerged, a new type of double glazing was developed.

Similarly to the ever-thickening walls conundrum, upgrading traditional sash and case windows to double glazing often means using bulky glazing units which ruin the fine lines of the transoms and astragals.

Vacuum glazing is similar to a double glazed unit in construction, except that it doesn’t have a gas in the cavity, it has a vacuum. That vacuum is far more effective than filling a 20mm cavity with a noble gas like Argon or Krypton, and therefore only requires a 0.2mm cavity - hence the unit’s thickness is greatly reduced. Some of the first vacuum glazed units to come to market are the AGC Fineo and the Pilkington Spacia; for example, a Super Spacia unit achieves 0.65 W/m2K, against standard 4+20+4mm double glazing which achieves around 1.2 W/m2K.

Thanks to vacuum technology, finally we have the potential to return to the slim glazing profiles and slender walls of the 1960's… and even more importantly, to use far less raw material in order to save much more energy, and in doing so to reduce the gross floor area of the building. That’s a triple win, and as a result you may not need to post your octopus through a Venetian blind after all.

Happy Christmas when it arrives. :-)

I’ve just seen an advert on TV for mail order food boxes: the soundtrack in the background is the song Enola Gay by OMD. The jaunty electronic pop tune is a tribute to, and lamentation over, the aircraft which dropped the first atomic bomb in anger. A strange choice for an advertisement, it’s almost as dissonant as the “advert” for itself which the BBC has been playing recently.

The climax of This Is Our BBC is a clip of Jimmy Reid explaining that “This is something for all of us.” Superficially, that’s what the BBC’s credo is, something for everyone in the UK. Yet I wonder whether the people who montaged all the video clips together have an inkling of what Jimmy Reid symbolises to folk north of the border. Reid took on the British Establishment, the System, the political machine, and won.

Some would argue that the BBC is the Establishment’s state broadcaster, and a po-faced one with an undeveloped sense of irony at that. So it would be rather amazing if the BBC imagined that *it* is a Jimmy Reid figure, swapping sides in 2022 to take on the Establishment in the form of a political elite which it has helped to prop up for the past century.

Meantime, I’m currently finishing off a project and yesterday was taken up with the laborious process of collating and uploading all the certificates needed for the CCNP, or “Construction Compliance and Notification Plan”. That includes an Emergency Lighting Installation Certificate, Electrical Installation Certificate, Fire Alarm Certificates, Air Testing Certificate, and CE marking on steel.

The biggest surprise came as I read the steelwork certificates. As I brought them together into one Acrobat file, I paused to read where all the steel originated. It was supplied by local stockholder, Brown & Tawse, whose HQ is just along the road at West Pitkerro, although they sourced it from much further away:

• Advance UCS’s from British Steel in Scunthorpe, a company now owned by the Chinese

• PFC’s from Celsa Steel in Cardiff

• CHS’s from Tata Steel in Corby, the plant which once belonged to Stewarts & Lloyds of Glasgow

• RSA’s from Liberty Merchant bar in Scunthorpe

• Smaller steel flats from Lamines Marchands Européens in Trith-Saint-Léger, France

• 152 x 152 UCS’s from Stahlwerk Thuringen in Unterwellenborn, Germany

• 254 x 254 UCS’s from ArcelorMittal Steel at Olaberria-Bergara in Spain

• Larger steel flats from Stahl Gerlafingen in Germany

• Rebar from Megasa Siderurgia Nacional in Maia, Portugal

• Handrail tubing from Çınar Boru in Turkey

• And finally, hot rolled steel plate from Hyundai Steel in South Korea

So despite Brexit, despite the Suez Canal incident last year, and despite calls to de-globalise, some of the steel has travelled several thousand miles. This matters, because imports cost money in fuel, import duty, and indirectly may end up funding people who we’d rather not support. No sign of Russia’s biggest steel producers such as Severstal, Evraz Group or Magnitogorsk Iron & Steel Works – but can you ever really know?

Of course, we used to make steel here in Scotland. The hot blast furnace was even invented here. But Corus has gone, and its predecessors too. Ravenscraig was an integrated iron and steel plant with the biggest hot strip mill in Europe. It was built by Colvilles, and if you work on older buildings, you’ll still notice that the webs of the beams are stamped Lanarkshire Steel Co. which was one of Colvilles’ subsidiaries. The steel which Brown & Tawse used to supply was made a couple of hours down the road.

We used to make steel here in Scotland, but the Scottish steel industry didn’t have a Jimmy Reid to fight for it. So most of it was destroyed by Thatcher's henchman Ian MacGregor, and what remained, including the mills at Clydebridge and Dalzell were sold off to the lowest bidder. Now when we complete our CCNP, the certificates resemble the entries in a Eurovision Steel Contest.

Scotland, null points.

Although it sounds like a mix by DJ Tiesto, it's actually a description of the reflex hinge (sometimes called a "friction stay") fitted to most of today's top-hung and reversible windows. Low stack refers to the depth of the hinge arms, Sinidex is a trade name and the Eurogroove is a standardised 18mm wide rebate in the jamb of the window frame. If the terminology means nothing to you, perhaps window specification is a more complex business than you realised...

At architecture school, I developed a hit-and-miss knowledge of windows from reading journals and occasionally picking up brochures and adverts from the trade press. In my first project at my first job after graduation, composite timber/ aluminium double-glazed windows were specified, and that was the starting point for a journey which gradually taught me about window technology.

Having previously specified NorDan, Velfac and Rationel windows on projects, a few years ago I spent a while collecting information then tried to compare the performance of all the composite window systems that were available in Scotland. Recently I revisited the exercise for a new project, and some changes are obvious. We've moved on from double glazing with low-E glass, and are on the brink of triple glazing becoming the standard.

Trying to find the perfect window? Sadly, it's like punching smoke. But unlike the DIY’ers, self-builders and internet wiseacres – architects have the advantage that we specify again and again, so we have some idea of how to measure success and failure. Plus we have access to proper technical resources such as BRE digests and TRADA research. That's important, because the modern window is a high tech enterprise and in order to specify well, you need to know a bit about building science.

For example, the window frame sections consist of many-times-machined timber and complex extrusions, with drips, anti-capillary grooves and fixings for gaskets machined in. The angles of components, the gaps between them, and the geometry of the labyrinth which prevents rain being driven towards the interior, are carefully calculated.

During the 1950’s, the English Joinery Manufacturers Association developed the EJMA “Stormproof” window, where the casement is outward-opening and sits proud of and overlaps the frame. This standardised design with its “weather check” replaced the various styles of flush casement windows common until that point, and for the next 30 years or so house builders had a simple choice: timber frames of standard quality, eg, Magnet & Southerns “M4”, or timber frames of slightly better quality, eg, John Carr/ Boulton & Paul.

The stormproof window was adopted in Scotland, but Scotland is and always has been different to the south. The lower temperatures and much higher exposure to wind-driven rain make our climate much more like Norway than Surrey. We've fitted windows into rebated jambs and set them back further in the opening for hundreds of years, whereas the English Reg's still allow you to fit windows flush against the ingo of the outer leaf or brick skin.

When double glazing started to come in, partly driven by the Technical Standards and partly by replacement window firms such as Everest, the EJMA Stormproof window frame sections had to be beefed up in order to compete. The first Scandinavian windows I came across were in the timber clad, timber kit Moelven houses that Aberdeenshire Council built across the field from my grandfather's farmhouse in Kemnay.

A single-glazed window (as originally fitted to buildings in 1960’s) gave you an overall U-value (Uw) ~ 4.8 W/m2K, but a typical PVC-U double-glazed window from the 1980’s (4*12*4 with air space between glass) gave you Uw ~ 2.8 W/m2K. Almost twice as good. In a country where it feels like the last big innovation was the duplex sash and case window, that was big news. Of course, with traditional sash windows, effective sealing is always in conflict with the operation of the window. This means a traditional sash window is either airtight and hard to slide open, or easy to open but draughty.

Scotland and Scandinavia can be very windy, so their casement windows have traditionally opened outwards and they developed effective drainage profiles and sealants because wind and weather proofing is important. As I discovered during my research, Scandinavian expertise lies in top-hung reversible windows (using "H"-type or Spilka) gear, with double-glazing and noble-gas filled cavity to give Uw ~ 1.3-1.4 W/m²K, improving to 1.1-1.2 W/m²K with low-E glazing.

By contrast, windows from Austria and Germany are often inward-opening, but they do get extremely cold winters, so good U-values are judged more important and they pioneered thermally-broken frames and “warm edge” spacers to improve them. Austrian practice is to use tilt & turn rather than reversible gear, with an insulated laminated timber frame and insulated glazing bead, plus triple-glazing and noble-gas filled or vacuum cavity; even in the late 2000’s, they could achieve Uw ~ 0.65-0.7 W/m²K.

What’s state of the art now? 92 mm window frames, now with 48mm triple glazing (4*18*4*18*4), which provides Uw ~ 0.8 W/m²K. That’s the level set for new build Passivhaus buildings, along with EnerPHit renovations in the cold climate zone, ie. northern Scotland. To achieve that, windows and doors are fitted into reveals with all edges taped using flexible foil tape, and the reveals sealed with Compriband externally and silicone internally

If you think glazing units are like razor blades, where manufacturers keep adding more and more blades to the cutting head … you’re right. While researching this, I discovered that the Scottish company Enviro make Uw = 0.35 W/m²K quadruple glazing. As far as I’m aware they’re the first in the UK, no doubt others will follow. Meantime I’ll end with a series of cutaway images showing some of the different frame profiles available on the market today.

In some respects it’s surprising that they’re so varied, and that makes specification more difficult since you’re not able to compare Coxes with Mac Reds, but the main two types are Alu-clad timber windows where the aluminium acts only as an external finish (almost like a rain screen cladding) and Composite timber windows where both the timber and aluminium parts are structural.

Alu-clad timber windows:

Rationel Auraplus, Uw = 0.79 W/m²K and lifespan of 80+ years with 4*20*4*20*4 (made in Denmark)

NorDan NTech One, Uw = 0.8 W/m²K and lifespan of 60+ years with 4*12*4*12*4

Optiwin Resista Modern, Uw = 0.64 W/m²K

Allan Brothers Horizont/ Alu Clad, Uw = approx. 0.9 W/m²K

Broxwood Alu-clad Timber Tilt & Turn, Uw = 0.7 W/m²K (made by Arbo in Latvia)

Katzbeck Combina Passiv, Uw = 0.71 W/m²K (made in Austria)

Norrsken P41A

HON Quadrat Studio FB, Uw = 0.85 W/m²K (made in Czech Republic)

Viking SW14 Uw = up to 0.60 W/m²K (made in Estonia)

Composite timber/ aluminium windows:

Velfac 200 Energy, Uw = 0.82 W/m²K and lifespan of 60 years (with 48mm glazing) 4*18*4*18*3, Uw = 1.06

IdealCombi Futura+, Uw = 0.74 W/m²K (made in Denmark); 4*13*3*14*4, Uw = 1.04

Gaulhofer Fusionline 108, Uw = 0.65 W/m²K

Internorm HF310, Uw = 0.62 W/m²K

Silber Fenster Passive, Uw = 0.71 W/m²K

Neuffer Eco Idealu, Uw = 0.78 W/m²K

Green Building Store “Ecocontract Ultra” (made in UK); 4*18*4*18*4, Uw = up to 0.68 W/m²K

Footnote - As with my piece a couple of years ago about electrical accessories, this is written from my own personal experience, and neither I nor Urban Realm have links to any of the manufacturers. Copyright in all images rests with the respective manufacturers.

Sometimes publication of a book traps an entire world in amber. In this case, The Information Book isn't Martin Amis's novel of a similar name, but a glimpse into Scottish architectural practice during the 1930's.

John Burnet trained at the Ecole des Beaux-Arts during 1870’s. Afterwards, he joined his father's practice Burnet Son & Campbell, and later established his own in Glasgow with a second office in London set up in 1905, after Burnet won a commission to design the Edward VII galleries at the British Museum.

One of Burnet's key assistants on the project later became a partner: Thomas Tait studied at Glasgow School of Art under the Beaux Arts teacher Eugene Bourdon (after whom the ugly brown brick building on Garnethill is named). By 1910, Tait was a leading member of Burnet's staff, and played an important part in the design of the Kodak Building in London, considered to be among the first examples of modern architecture in the UK.

Tait worked for a time in New York and was a highly skilled perspectivist, but is best remembered nowadays for Tait's Tower at Bellahouston Park, part of the 1938 Glasgow Empire Exhibition. Other notable works include St. Andrews House on Calton Hill in Edinburgh and Hawkhead Hospital in Paisley, along with many projects in London.

The third leg of the partnership was Francis Lorne, who was by all accounts a skilled manager and also became the spokesman for the practice, arguing that Modern architecture required “a change of heart … only by getting back to architecture as a practical building problem for our own country, our own people, our own climate and conditions of life, can we produce an architecture that will mean something.”

The firm became Burnet, Tait & Lorne in 1930, and the expat Scots working from Glasgow and London grew into the leading British architectural practice during the 1930's, in a way that wasn't repeated until RMJM's glory days of the 1960's. Big cities are full of opportunity if you're in a position to seize it, which Burnet, Tait & Lorne were able to do during the inter-war period.

It was Francis Lorne who wrote the book “Architectural Office Administration” in 1921, then a decade later pulled together The Information Book of Sir John Burnet, Tait and Lorne, which should be better known as it's the prototype for the New Metric Handbook, The Architect's Pocket Book and pretty much every other guide to design practice which followed.

Today The Information Book is the best work of reference for 1930’s and 40’s era buildings in Scotland, and the rest of the UK. It’s coloured by the dual influence of North American practice in steel-framed medium-rise office blocks which was particularly influential in Glasgow, plus the Art Deco and Moderne buildings erected in London between the wars which prefigured full-blown Modernism.

Its genesis is described in Christian Barman in the book’s Foreword (for greatest effect, read out loud in your best imitation of Miles Cholmondley-Warner):

“The need for a great compendium of information first impressed itself on me some five or six years ago, when I had not long taken over the Editorship of Architects’ Journal. The more the task was studied, however, the more difficult it seemed. … The thing was just about as much as a commercially produced periodical, however well intentioned, could ever dare to consider.

“Then, one day, good luck brought a sudden and, I feel, a most happy solution. Chancing to be at the house where my friends Thomas Tait and Francis Lorne maintain their finely staffed office in partnership with Sir John Burnet, RA, I saw a draughtsman coolly turning the pages of the book of my dreams. … It did not need a close scrutiny of the Information Book to convince me that it was a very superior specimen of the kind of thing I had myself been trying to bring about.”

First published in 1933 by the Architectural Press, in the days when that was run by the splendidly-named Hubert de Cronin Hastings, The Information Book begins with a couple of chapters on the Secretarial Department and Draughting Department. These describe what we’d now call practice management, and are followed by a series of 147 Information Sheets which cover everything from construction details, brick and board sizes, terminology and electrical symbols to extracts from the Building Regulations.

It may have begun as an in-house guide to Burnet Tait & Lorne’s office standards and procedures, but The Information Book became universally useful, and Lorne wasn’t the only one to think that a book like this could be handy. In 1932, “Architectural Graphic Standards” appeared in the US, and twelve editions later it’s still in print and has developed into a doorstop-sized handbook of typologies, ergonomics and design data. Similarly, Architects' Data, universally known as “Neufert”, was first published in Germany in 1936, and after many German editions it was translated into English in 1970 and published by Lockwoods.

The simultaneous emergence of these three books demonstrates that the 1930’s was an inflection point, where the Modern Movement and its modern methods of construction became properly mainstream. Structural steel and concrete frames were being widely adopted, so our day-to-day knowledge had to extend beyond traditional building techniques. As Barman says in his introduction to The Information Book, “It only seems the other day that the main facts about building science could still be got between the covers of a book of average size”. No longer.

Neither Neufert nor the later New Metric Handbook tries to cover as much ground, from practice management to design data, as The Information Book - but during the intervening forty years so much extra information has come into the world that an architectural “book of everything” would be a massive tome. As it is, Neufert weighs 2kg.

Reference works such as The Information Book and its cousins were essential in the pre-internet world. I entered practice at the changeover, when CD-ROM’s and early webpages had begun to supplant technical books. But we still hung on to brochures and supplements which included priceless information, like the Corus steel sections booklet or Pilkington’s glass guide. They provided a safety blanket of reassurance, even if you rarely needed to consult them.

Today, Burnet Tait & Lorne’s Information Book is a reminder of two things: firstly that the state of the art eventually becomes a quaint curiosity lurking in an antiquarian’s back room; yet the book also retains some usefulness. It’s one of the few places where you can see how buildings from the 1930’s and 40’s – of which there are hundreds of thousands still standing – were put together, and how we went about achieving that.

ps. Note to book dealers researching their catalogues - please credit me and link to Urban Realm if you find the information in this piece useful. :-)

Searching for a taste of the exotic? 100 years after Modernism began, more or less, with the founding of the Bauhaus, there’s a conventional palette of materials which we still use. Scotland’s traditional materials like rubble masonry, red deal, slate and harling were supplanted early in the 20th century by beton brut, engineering brickwork, blonde timber and stainless steel. They’re still widely-used, even though none are particularly modern any more.

But Modernism had another strand, exemplified by the Barcelona Pavilion and Aalto’s private house commissions in Finland. Those used a richer palette of leather, darker timbers, bronze and marble. Many of the projects which feature in glossy design magazines today still use this “luxury” palette. No MFI kitchens and laminate flooring for them…

At the moment, I’m working on a range of projects including a centre for people with autism, an aviation academy and a Grade A fit-out for corporate lawyers. As you’d expect, the first one conforms to strict guidelines, the aviation project has an engineering bias, and the lawyers lean towards a sombre palette which is radically different to what the computer games developers in a nearby block wanted.

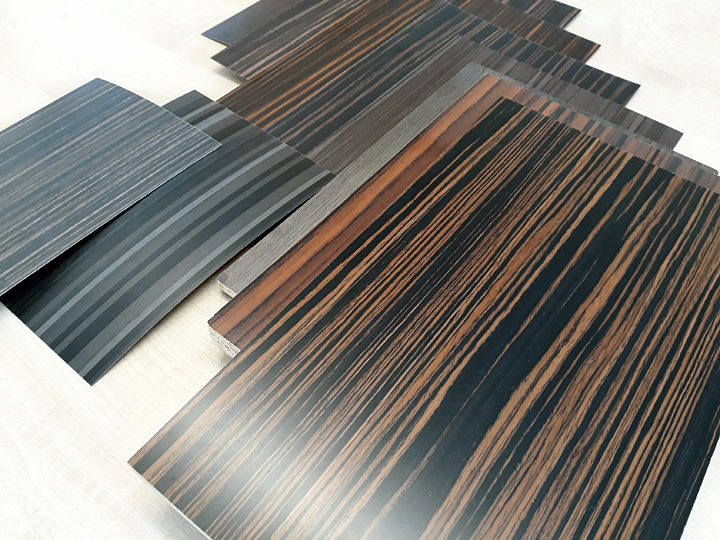

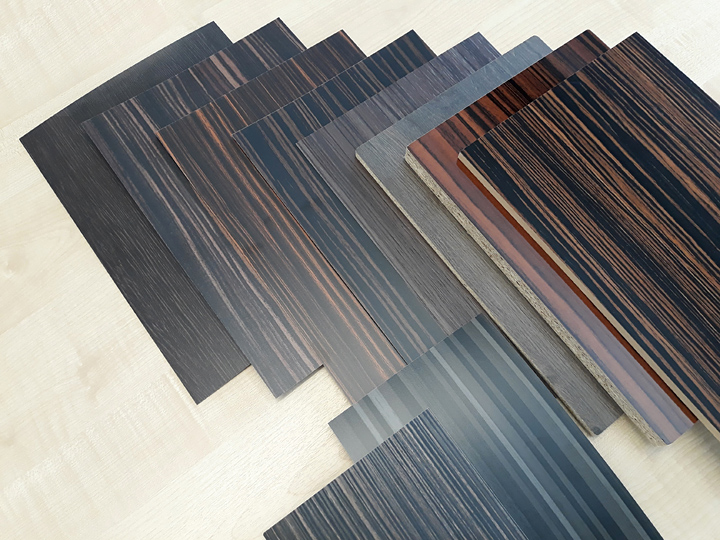

The lawyers’ office suite looks out over the firth, and the internal doors are finished in a veneer which has parallel stripes of very dark brown to black, alternating with lighter bands of golden brown. At first I thought it might be Zebrano, but having consulted the Architect’s Giant Bedside Book of Exotic Veneers, I think it’s actually Macassar Ebony.

Some use “Macassar” for any Ebony with prominent light and dark streaks, but it’s generally acknowledged as Diospyros celebica. Both Zebrano and Macassar veneers came into fashion a few years ago, but remain in the timber trade’s highest price group. For example, Range Rover use Macassar for dashboard and door cappings, even though their Chief Designer, Colour and Materials, Amy Frascella suggested in an interview I read that there’s a shift in favour of reclaimed and non-leather materials in what she calls post-industrial colours.

That might mean vegan-friendly polymers and fake “pleathers”, plus sustainably-sourced timbers or even post-consumer recycled material. For example, waferboard, strandboard and OSB are different names for the same thing, a board pressed from sawmill waste. Carbonfibre is another possibility, at least in sports cars, and various man-made luxury textiles such as Alcantara.

Natural materials have different advantages, but in all conscience some timbers are difficult to spec, because tropical hardwoods grow very slowly. Teak and Mahogany were popular in the 1950’s and 60’s, but that popularity meant swathes of rainforest were felled and we began to seek alternatives, such as Sapele and Jatoba. Yet timber is only truly sustainable if you plant a tree every time you chop one down – and if you’re prepared to wait for several generations before you harvest that patch again.

As I was hunting for a match for the Macassar wood, I spoke to several veneer suppliers, one of which was located in the East End of London. The cheerful Cockney technical rep decided to have a word in my shell-like, as Arthur Daley would say: “That looks like a laminate rather than a veneer, mate – an expensive high pressure laminate, but it’s a laminate nonetheless.” Cheers, geezer.

It makes sense when you understand the context. Macassar Ebony is rare in veneer form because the trees don’t grow particularly tall, so finding boles large enough to cut door-sized sheets of veneer from is difficult. The small sheet size makes the veneer more suitable for cabinetry, inlay work and making musical instruments. Macassar is also a tropical hardwood, which while not listed in the C.I.T.E.S. Appendices of endangered species, it’s definitely on the I.U.C.N. Red List of vulnerable trees.

The trees are native to the Celebes Islands in the East Indies and they’re named after the Indonesian port of Makassar, which was the main point of export. They’re also found in Maluku and Borneo – although back in the day, many shipments came through India and Sri Lanka. Until the 1970’s, Holt’s Blue Funnel line ships called at the less well-known ports of Sumatra, Java, Borneo and often took on cargoes of exotic hardwoods. Nowadays, due to the trees’ rarity and our concern about the sustainability of tropical hardwoods, Ebony is rightly difficult to get hold of.

It was always thus. Ebony wasn’t readily available in Europe until the 1600’s, although the Greek historian Herodotus records that Ethiopia paid an annual tribute of 200 ebony logs to the Persian Empire. After the 17th century, woodworkers in France perfected the craft of veneering with ebony for furniture and cabinetry and even today, France cabinetmaking is called ebenisterie and a cabinetmaker is known as an ebeniste.

So that explains why Macassar laminate is an acceptable substitute for the real thing. After speaking to the cheerful Cockney, I called up Herodotus on the blower - but he was out of stock, and anyhow doubted whether he could get veneer into the country due to the Brexit Effect. So the moral of this story is that we’re in the market for a convincing laminate, weighing the efforts of Formica, Egger, Resopal and Polyrey.

The best match so far comes from Formica, which captures the colour and tone of a real Macassar Ebony, as well mimicking its texture. Whether or not the lawyers realise it, their choice of door finish is a modern facsimile of an exotic tree which is amongst the aristocracy of timbers. In fact, we covet Macassar wood, and its rarity, so much that we’ve almost logged it into extinction.