Shoreham Cement Works

13 Jan 2014

Mark Chalmers underwent a recent pilgrimage to a cathedral of concrete in West Sussex, Shoreham Cement Works. On entering he discovered a hidden world which has cemented its reputation as an urban explorers paradise. Here we investigate its deepest nooks and crannies.

Looking at the giant red towers of Bofill’s project, it’s hard to imagine anything further from that rude shack, even though both Thoreau’s novel and Bofill’s vision were intended as “experiments in living well”. Thoreau felt that, “a great proportion of architectural ornaments are literally hollow, and a September gale would strip them off, like borrowed plumes, without injury to the substantials.”

Mind you, there’s nothing more substantial than an old cement works, so perhaps Thoreau would approve of Bofill’s post-modern monumentality and appreciate the challenge of recasting other old cement works. The most abandoned of those lies on the Channel coast of Sussex, a vast structure which has lain quiet for two decades, since it was shut down by Blue Circle Cement.

During the 20th century, Blue Circle was one of the biggest names in the construction industry. Although it later spread its wings into Armitage Shanks bathrooms, Myson radiators and Potterton boilers its mainstay was cement, the grey powder which gives birth to architecture.

Cement powder, properly called Ordinary Portland Cement or “OPC” is the fundamental ingredient in every building: without it, concrete wouldn’t exist, nor would the mortar which holds masonry together, or the grout which waterproofs joints. Thanks to its strength, plasticity and economy, concrete became the universal building material.

Portland cement was patented by Joseph Aspdin in 1824 and for decades afterwards, it was made in small bottle, beehive and chamber kilns. The process is a simple one: you heat a mixture of finely-ground limestone and clay to create cement, a powder which hardens with the addition of water. Aspdin named it “Portland” because it resembles the stone quarried on the Isle of Portland.

A few miles along the coast from Portland, a chalk pit existed at Upper Beeding from at least 1725, but during the 18th and 19th century most of its chalk went for lime burning. Cement production began in 1850, and by the 1880’s the six chamber kilns were producing around 7,500 tons each year. In 1897, the Sussex Portland Cement Co. of Newhaven bought the works, and began to expand it.

Three years later, the Associated Portland Cement Manufacturers (APCM) coalesced from the multitude of small cement producers in the south-east of England. Around the same time, the rotary kiln was introduced, improving the efficiency of the process and thus revolutionising the industry. One of the cement works which benefitted from both was that small plant in the valley of the River Adur at Beeding.

The 1910’s and 1920’s were thin decades, but as the construction industry recovered from the Great Depression, APCM decided that Beeding should be rebuilt with rotary kilns on a grand scale. During the mid-1930’s, a new cement works was planned in the mouth of the chalk quarry: clay would be won from pits a short distance up the Adur, and coal was brought in by rail.

Construction began in 1948, and appropriately much of the new cement works was built using reinforced concrete. The buildings were designed by Oscar Faber, the structural engineer who pioneered the use of “ferro-concrete” in Britain. Although Faber remained in the shadow of another emigré engineer, Ove Arup, he was the expert in reinforced concrete during the 1950’s. The cement company’s engineer at the time was George Rheam, so the monumental project became known locally as “Rheam’s Cathedral”…

Big and bluff with vaguely Art Deco details along its frontage, the new works was the first of its kind, and was equipped by machinery made by Vickers-Armstrong. Better known for building battleships, Wellington bombers and VC10 airliners, Vickers got into the cement business during the post-war building boom. At the time, arms manufacturing was in decline, but concrete was a growth industry.

During that era, the Vickers company made ships, bulldozers, steel and cement plant. In due course, its management saw more promise in ships and steel than bulldozers and cement, because margins on the former were good, whereas each time the construction industry suffered a slump, the factories which made bulldozers and cement plant stood idle. Today, the military side of Vickers Shipbuilding and Engineering is part of BAE Systems, whereas the construction side of Vickers-Armstrong effectively doesn’t exist.

APCM became known by the trademark on its cement bags, a blue circle, and eventually the firm changed its name to suit. The cement works at Upper Beeding was a success, and afterwards Vickers and Blue Circle collaborated to create a series of further cement works, including Westbury and Northfleet, the latter of which became the largest in the world.

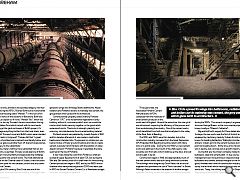

The pair of giant rotating kilns, called C1 and C2, are 350ft long by 10ft in diameter, and were constructed in a huge hall. It was common practice to mount coolers directly under the kilns, which is why the concrete piers they sit on are so high. As a result, the kiln hall is as tall as a cathedral’s nave. The clinker mills, with their bright yellow motors, were housed in an adjacent block. All were built by Vickers’ factory in Barrow-in-Furness, and formed the first installation of a design which was subsequently used elsewhere.

Chalk blasted from the quarry face was conveyed to two sets of crushers, then transported into the main building where it was sorted and blended then made into slurry. From there, it entered the pre-heating tower, which drew waste heat from the kilns to bring the slurry up to their steady operating temperature of 1400°C. The kilns themselves are insulated with two layers of refractory bricks, and were driven by securing steel tyres at intervals along the kiln shaft, which sit on rollers powered by electric motors geared down to drive the kilns at around 3rpm.

The chalk slurry was fed into the kilns, then pulverised coal was blown in and ignited. The heated material was driven along the kiln by the slight gradient, and by new material being fed in from the pre-heaters. Passing through steadily hotter zones turned it into a semi-molten state, and it began to change in composition. The red-hot clinker then dropped into cooling tubes, and the waste heat was captured using blowers.

Molten cement clinker at 1400°C gives off vast amounts of heat, so the tyres around the kiln have to be “chaired” from the main drums to avoid absorbing too much. Similarly, the kilns were fitted with damper weights suspended on wire cables to prevent vibrations breaking them apart. Another risk was a power outage which stopped the kilns turning: the temperature differential between the top and bottom of the kiln would cause them to warp and buckle on their rollers, turning them into expensive chunks of scrap metal.

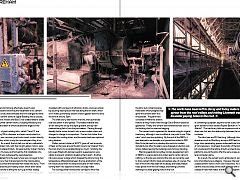

The cooling clinker moved onto conveyors which fed ball mills, which are huge drums similar in appearance to the kilns, but containing large metal balls which progressively grind the cement down to a fine powder. The plant here consisted of Metrovick electric motors driving Vickers mills through David Brown reduction gearboxes. Finally, the cement was transferred next door to the holding silos for eventual bagging.

The cement works operated for decades using its original machinery, although it was modified at one point to use “filter cake”, which was less polluting. By the end of the 1980’s, it was deemed to be obsolete, and production ended in 1991. Blue Circle planned to re-develop the works to modern standards, but after the plans were dropped production was simply halted, leaving the buildings and chimney standing.

Planning applications by Blue Circle’s development arm in 1988 for a science park and winter sports centre came to nothing, so the site was sold and the silos are currently used to store cement (that’s made somewhere else, of course). The rest of the works has been left to decay, and today mature trees sprout from the roof valleys, and rotting Lionweld walkways lie under gaping holes in the roof.

Now, the most striking impression of the cement works is of something cyclopean, beyond human scale, rather like the grain elevators which excited Reyner Banham in “A Concrete Atlantis”. The machinery halls are impressive not only for their sheer size, but also the relationship between the vessel and its container.

The kilns here are 350 feet long, (although those elsewhere such as Westbury are up to 600 feet long), and the huge, inter-penetrating spaces underneath are lined by sets of concrete piers. Overhead, the solidity of the boiler-plated kiln counterpoints the lattice of built-up steel trusses, and the platforms around the kilns offer the same scope as a multi-level computer game.

As a result, the cement works embodies its own particular kind of architecture as allegory. However, the real message of a dead cement works is how cold it becomes. As with brick, ceramic tiles and steel, all the stuff we build with is formed in a blaze of heat: that makes it all the more poignant to see a cement kiln once its flames have been doused.

|

|

Read next: Scotland's Top Architects 2014

Read previous: Lateral North

Back to January 2014

Browse Features Archive

Search

News

For more news from the industry visit our News section.

Features & Reports

For more information from the industry visit our Features & Reports section.